High-Quality Plastic Injection Molds

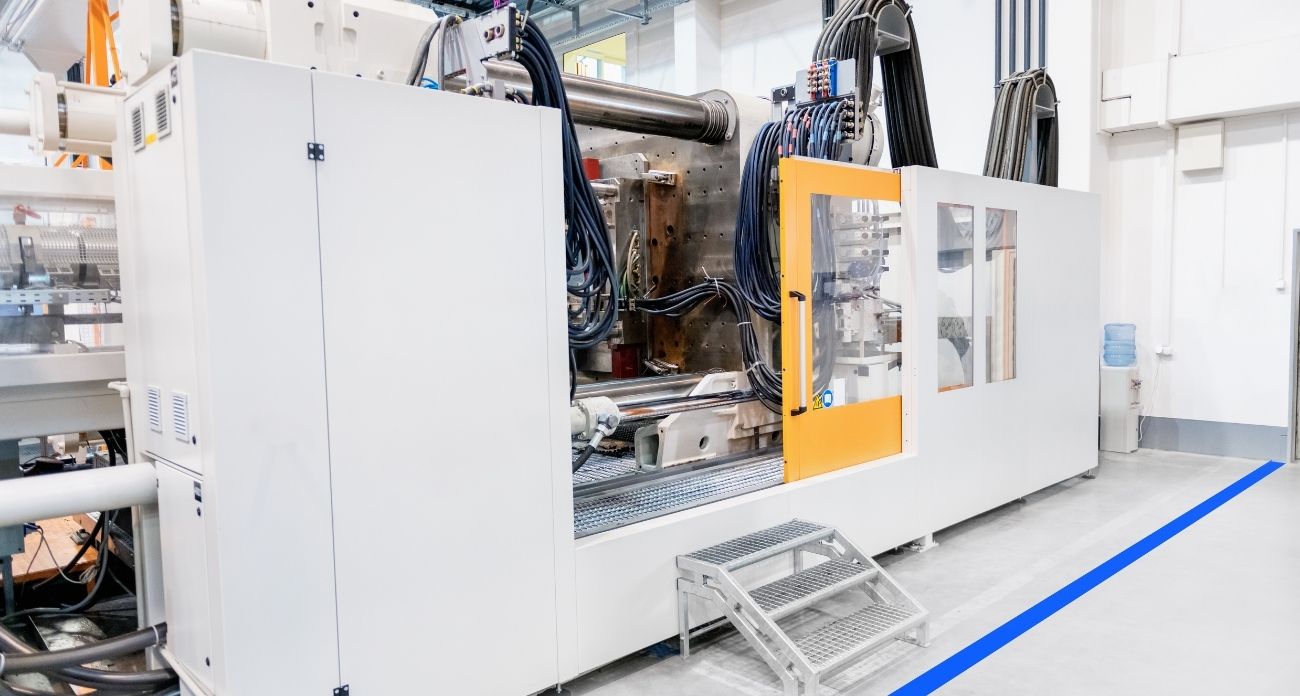

The molds, which are shaped in line with the needs of the customers, are prepared in a way that is suitable for producing plastic. Plastic injection molds are designed and manufactured by experts in the field. Molds produced in the machine are used in many areas. It is designed with 3D CAD surface and solid […]

Hot Runner Systems in Plastic Injection Molds

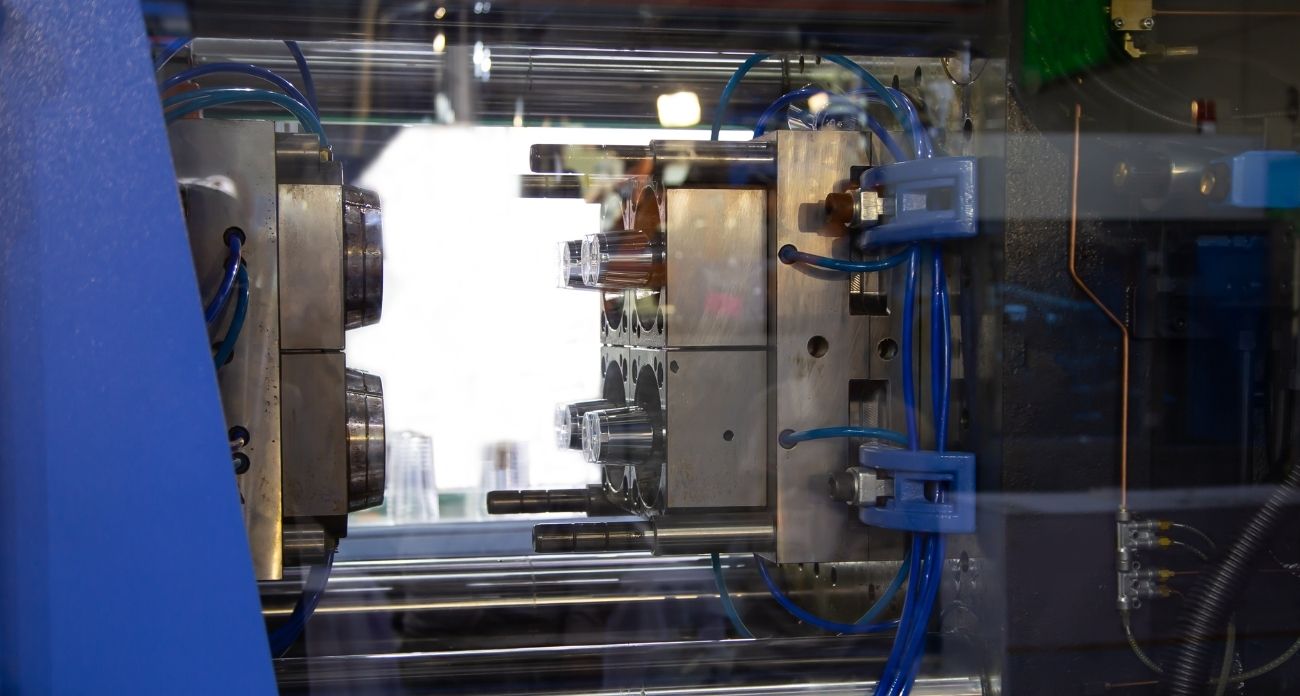

One of the methods used for shaping plastic material is plastic injection molds. These molds allow the plastic material to be shaped in the mold by melting it under high temperatures. Thanks to plastic injection molds, the size, shape and quality of the product in question are determined through molds. The hot runner system, which […]

What are the IML Label Types in Thin Wall Plastic Injection Molds?

Thin-walled injection molding is a short-term and low-cost method. It is used in sensitive areas such as food and beverage, automotive, medical products, flower pots, storage containers, computing equipment and mobile telecommunications. The IML labels used in these injection molds have different types. What are the Advantages of Thin-Walled Injection Molding? Thin-walled plastic injection, which […]

What is Injection Mold Design?

Injection molds are products made of durable and hard metals such as stainless steel, steel or aluminum and can be reused for many years. Injection mold design is one of the most common types of molding used today for both consumer products and engineering applications. Almost every plastic product you see around is produced using […]

Where are Plastic Injection Molds Used?

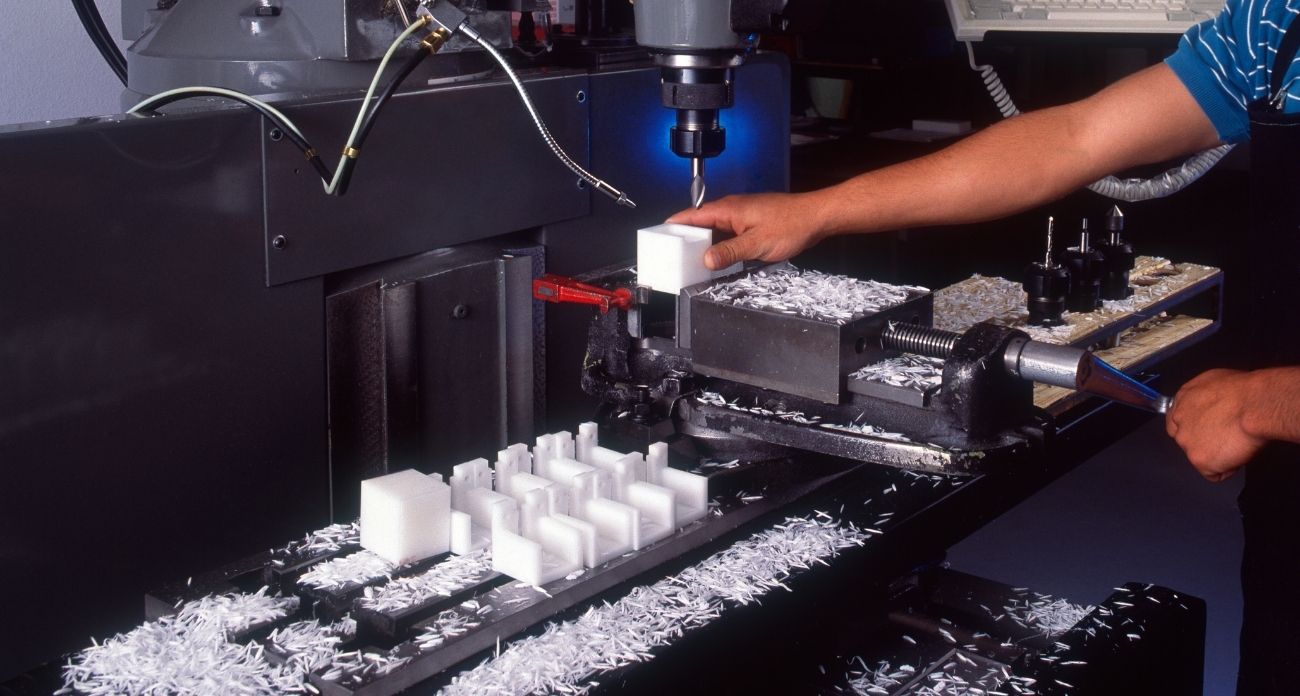

Plastic injection molds are tools used to produce large quantities of plastic products. For the plastic melted in injection machines to take the shape of the product, they need plastic injection molds in suitable forms. After their designs are completed, the molds must be manufactured with the help of high-precision CNC machines. Plastic Injection Mold […]

How Thin Can Plastic Be Molded?

Plastic molds have an important place in the industry. Molds of industrial products and consumables are made in every field from food packaging to cosmetic materials. These molds are mass produced in certain sizes and wall thicknesses. Moldmore, a plastic injection molding company with a rich product range from yoghurt containers to cheese containers, from […]

Advantages of Packaging Produced with IML

IML technology provides high quality labels and makes the appearance of the products aesthetically pleasing. IML helps to realize permanent and long-lasting designs. The packages produced with this technology have eye-catching designs. While the IML production technique provides many benefits to the users, the designs produced also offer different advantages. What are the Features of […]

What is In-Mold Labeling (IML)?

IML is carried out by placing the Polypropylene product, which has been pre-printed, into the mold. This product melts into the label and becomes the final design. What are IML Usage Technologies? IML technology means effective labeling of plastic packaging products. This technique, which is widely used in Türkiye, is one of the latest innovations […]

How is the Wall Thickness Determined for an Injection Mold?

Plastic injection mold is widely used in industry. The most important reason for this is the practical production of seamless plastic products in desired shapes and sizes thanks to injection molds. Molding plastic products is subjected to different parameters. In injection mold works, the wall thickness, the problems likely to be caused during the production […]

What is IML? What are the Usage Areas?

IML or InMould stand for in-mold labeling. In-mold labeling is used in many different industries. For this reason, it is among the best packaging methods for companies producing plastic packaging. In-mold labeling is essential for memorable and eye-catching packaging. In-mold labeling technology differs from traditional decoration processes such as digital printing, flexography, letterpress or offset, […]