What are the IML Label Types in Thin Wall Plastic Injection Molds?

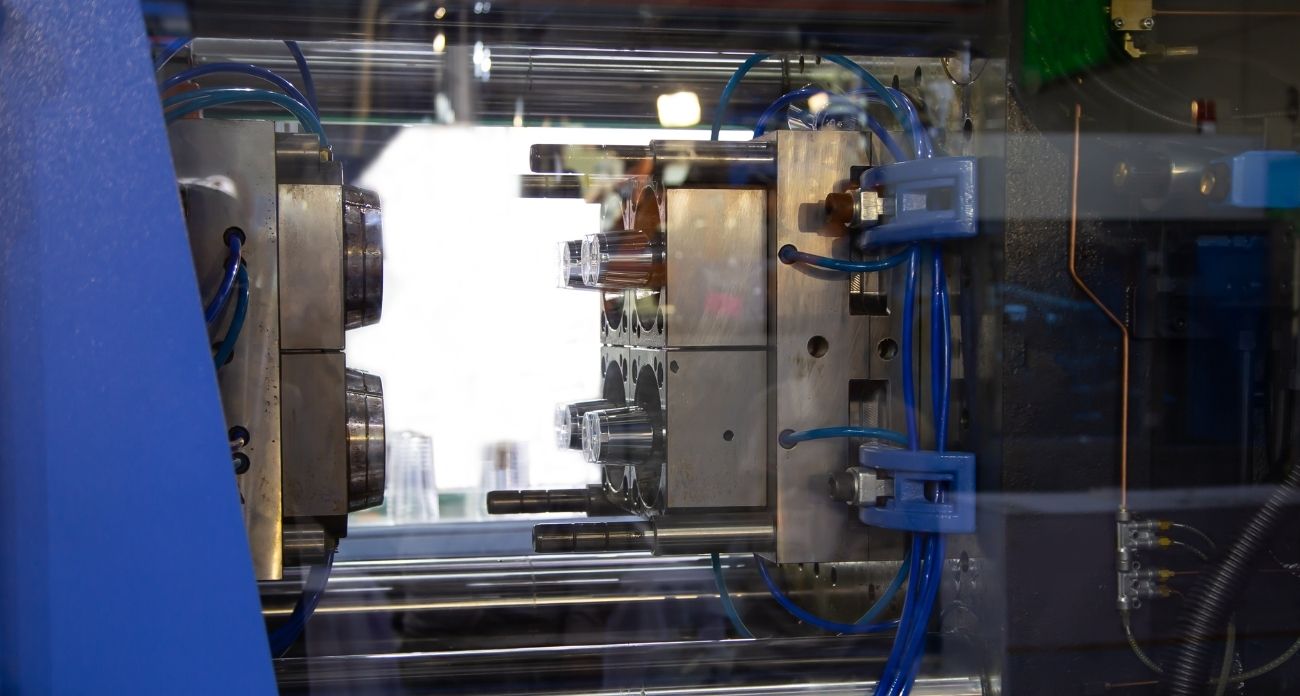

Thin-walled injection molding is a short-term and low-cost method. It is used in sensitive areas such as food and beverage, automotive, medical products, flower pots, storage containers, computing equipment and mobile telecommunications. The IML labels used in these injection molds have different types.

What are the Advantages of Thin-Walled Injection Molding?

Thin-walled plastic injection, which is a special manufacturing method, is related to the proportionality of the wall thickness and the size of the part. This method is used in many sectors and widely preferred by manufacturers thanks to the benefits it offers. The advantages of this form of molding are:

- Creating low-cost, reliable and clean plastic parts,

- Reducing fuel use,

- Using recyclable plastic materials.

What are the IML Label Types?

Offering high print quality, IML is the abbreviation of in-Mold Labeling. This system ensures that the packaging cost is economical. It is preferred in various sectors such as cosmetics and paint. IML tags made with this effective and fast packaging technique are seen as a part of the area where they are located. Usage technologies of labels are:

- Injection,

- Thermoform,

- Blow molding.

It gives structural stability to thin-walled containers. These labels are completely recyclable, with a robust and hygienic structure. Forms of mold packaging can be square, oval, rectangular, cover and custom design. Types of IML tags used are:

- Plain Patterned,

- Transparent,

- Inflation,

- Orange Patterned,

- Pearlized,

What are the Factors to be Considered in Patterns Suitable for IML Technology?

IML labels emerge when the mold, robot, injection machine and label parameters work in harmony. The main features of the molds suitable for this technology are:

- Using a healthy cooling system that shortens the mold manufacturing process,

- The selection of materials used in the mold and the added engineering, labor and heat treatment are the same,

- Designing molds suitable for the sector, for wrapping and base, U or cross-shaped labels,

- Selection of robot technology suitable for in-mold labeling technology,

- Preferring a hot runner and heat control system with low wattage and suitable needle structure.

For detailed information about IML labels, you can contact the MoldMore expert team.