How Are Plastic Injection Molds Made?

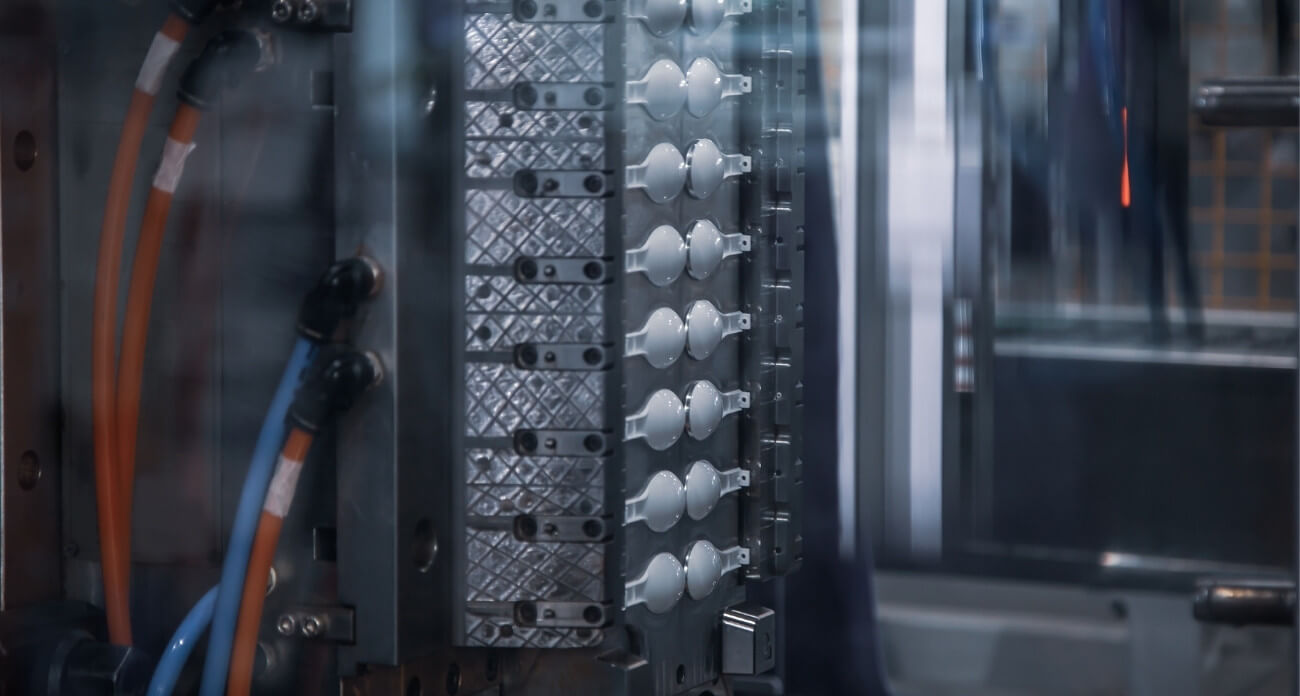

Plastic injection molds are specially designed molds that are injected into the melted plastic raw material to shape it. The melted plastic raw material is formed inside the injection mold. Once the plastic raw material cools down, the desired product is obtained after being removed from the mold. The production method with plastic injection is frequently used in the industrial field. Many apparatuses that human beings use in their daily lives are produced using plastic injection method. So, how are plastic injection molds, which have an important place in human life, made?

Why Plastıc Injectıon Molds Are Preferred?

Plastic injection molds have significant contribution to manufacturing with their advantageous features such as the ease of use and obtaining more products. Plastic injection molds are among the indispensables of manufacturers since plastic products attract attention in almost every sector. Although the cost of plastic injection molds is high and the delivery times are long, manufacturers often prefer plastic injection molds. There are many valid reasons for this. Plastic injection molds:

- are resistant to corrosion,

- offer the possibility of patterns,

- are resistant to high temperatures,

- are resistant to abrasion,

- enable surface-based processes,

- can be polished,

- are easy to process,

- enable mass production,

- provide the opportunity to obtain many products

How are Plastıc Injectıon Molds Produced?

The production of plastic injection molds used in the production of many apparatus goes through several stages. First of all, the designs of the molds are made. Molds designed in computer environment are combined using CAD or CAM programs. The shape and dimensions of the product are significant when making plastic injection molds. Therefore, plastic mold elements differ according to the product and the size of the mold. Machines such as CNC, plunge erosion, milling and lathe are generally used in the production of plastic injection molds. It is processed with the mentioned machines using aluminum or tool steel, and then produced according to the desired standards.

The surface texture and geometry of the parts to be produced using the mold is transferred to the molded part by direct injection. The high level of expertise required to design and manufacture a high quality mold capable of producing hundreds of thousands of parts increases the initial cost. Another reason why injection mold costs are higher is that a special mold is made for each geometry. For this reason, initial costs constitute the largest part of the work in the production of plastic injection molds. For detailed information about plastic injection molds, you can contact the Moldmore expert team.