How Thin Can Plastic Be Molded?

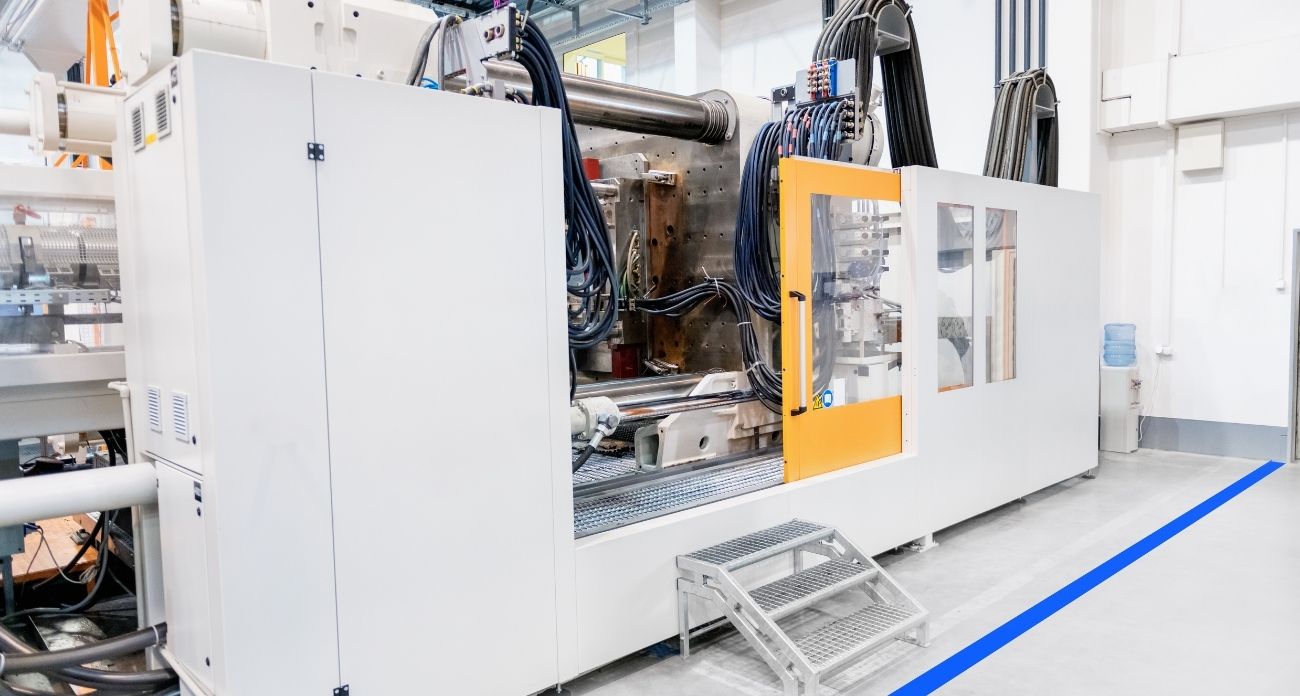

Plastic molds have an important place in the industry. Molds of industrial products and consumables are made in every field from food packaging to cosmetic materials. These molds are mass produced in certain sizes and wall thicknesses. Moldmore, a plastic injection molding company with a rich product range from yoghurt containers to cheese containers, from toys to cosmetic products, is one of the leading companies in the sector in Turkey. The brand makes designs following technological trends during the production of plastic molds and delivers products with the appropriate optimum weight to its customers at the fastest speed with its expert staff.

The correct assignment of wall thicknesses during mold design are factors that directly affect the properties, weight and strength properties of the part. Plastic mold thickness is usually designed between 0.06 inch and 0.25 inch. This means that it can be produced in dimensions of approximately 1.5 mm to 6 mm. Products thinner than 1.5 mm may cause problems in terms of the strength of the product.

Why is Wall Thickness Important in Plastic Molding?

It is important to determine the wall thickness correctly during plastic molding. If the part is too thick, collapses on the part become visible. At the same time, distortion and internal cavities in the part may occur. Similarly, a thinner wall thickness than it should be can cause various problems. To avoid such situations, correct dimensioning tables should be used on a product basis. Plastic molds are put into production in the form of plastic injection molds with the infrastructure of modeling and simulation programs. Plastic injection molds are the most preferred plastic mold options.

What Should Be Considered in Plastic Mold Design?

Plastic mold works are productions made on completely personalized solutions. Maintenance and revisions of all plastic molds manufactured are also included in the process. In plastic mold design, the main purpose is to design products with high strength. Quality products suitable for the weight of the product and suitable for weight measurements are designed. Designs that meet the expectations of the customer and the features of the product are offered at various price ranges. Moldmore manufactures by using up-to-date technologies and production techniques through its expert staff. You can contact the Moldmore expert team to get detailed information about plastic mold designs.